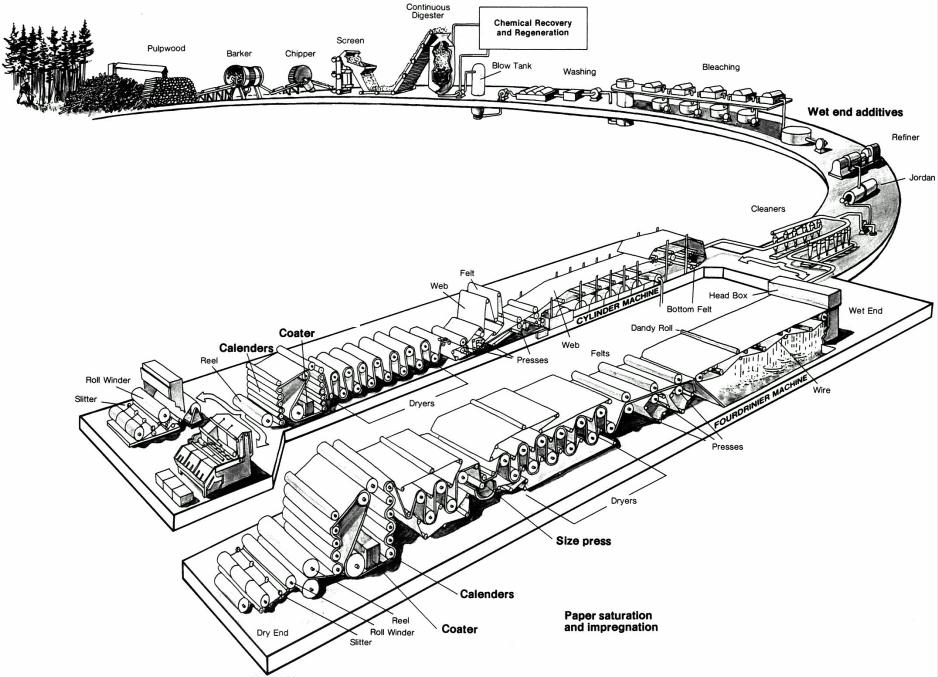

Paper Manufacturing Overview

Background and Applications

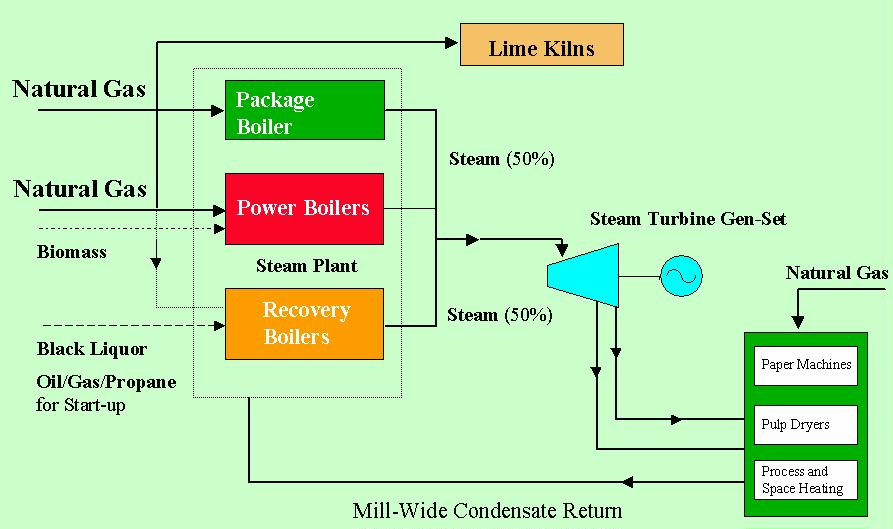

Paper manufacturing is a very energy intensive process. About one-half of the total energy used is in the pulping process, which is the cooking of the wood chips to open the fibers that create the paper materials. Therefore, a mill that is ‘integrated’ (it includes pulping and paper manufacturing), will use at least twice as much energy as the same size mill that uses ‘market pulp’ (pulp produced at another location and sold as a raw material). The largest single energy user at a paper mill is boiler fuel. The graphic below shows the major thermal energy flow through the conventional integrated mill.

Paper Mill Boilers

Packaged Boilers are typically natural gas or oil. Power House boilers are typically coal, wood waste, black liquor, oil, natural gas, or multi-fueled, depending on the size of the mill and if it includes a pulping operation. It is common for several different kinds of boilers to be used at the same mill. Most mills also include a steam turbine(s) to generate electricity. This may be because the mill is older than the public electric system in the area, but continues to make operational sense. The boilers produce high pressure steam (in excess of 500 psi) that first passes through the steam turbine. The steam turbine takes energy out of the steam by reducing its pressure to about 100 psi, which then runs the rest of the mill. Mills may also have direct steam drives in areas that would otherwise have electric motors. Steam drives resemble mini-steam turbines, and are much smaller than an electric motor of the same horse power. For more information about Steam and Boilers, please visit the Energy Solutions Center’s Boiler Burner Consortium web site at www.CleanBoiler.org

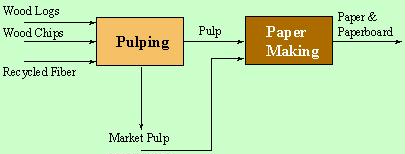

Pulp Manufacturing

There are three basic methods to produce pulp: Mechanical Pulp (yield 90%) Mechanical pulping uses mechanical abrasion to separate cellulose fibers which are held together by a material called lignin. In the process called “Groundwood” wet wood is ground by large stones. In Thermo Mechanical Pulping (TMP), metallic plates rub steam heated chips at high speeds, separating fibers Chemical Pulp (yield 50%)  Uses chemicals to dissolve lignin. Kraft pulp is most common pulp. Semichemical Pulp Uses chemicals to soften lignin, and mechanical abrasion in refiners – Chemi Thermo Mechanical Pulping The kind of paper that can be made is determined by the wood fiber and other raw or recycled materials used and the pulping method. If the pulp will not be used on-site it becomes “Market Pulp”, and shipped to another location. Due to many factors but mostly environmental and local wood supply, many mills no longer produce their own pulp. Before the pulp is shipped, it is dried on a machine called a Flakt Dryer. The Flakt Dryer has multi-level decks or webs with steam-heated air jetted through the pulp and rollers that squeeze it to remove the water.

Uses chemicals to dissolve lignin. Kraft pulp is most common pulp. Semichemical Pulp Uses chemicals to soften lignin, and mechanical abrasion in refiners – Chemi Thermo Mechanical Pulping The kind of paper that can be made is determined by the wood fiber and other raw or recycled materials used and the pulping method. If the pulp will not be used on-site it becomes “Market Pulp”, and shipped to another location. Due to many factors but mostly environmental and local wood supply, many mills no longer produce their own pulp. Before the pulp is shipped, it is dried on a machine called a Flakt Dryer. The Flakt Dryer has multi-level decks or webs with steam-heated air jetted through the pulp and rollers that squeeze it to remove the water.

The Kraft Liquor Cycle

The pulping process produces a liquid byproduct called ” -color- liquor”; it’s -color- is dependant on the process and where in the process the liquor is at. Liquor has many propertied, including flammability, and can therefore be used as a source fuel. For more information Paper Kraft Liquor Cycle

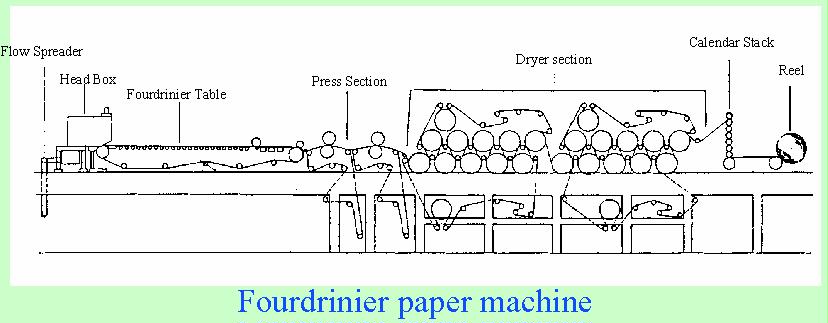

Paper Machines

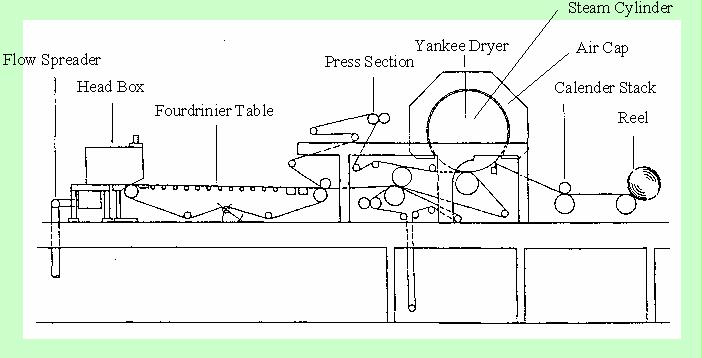

The same paper machine line can be used to produce a hundred different kinds of paper, depending on the kind of pulp, thickness and line speed. Paper can vary from very thin, high quality “Bible Paper” to very heavy, low quality box or kraft paper used to make ‘cardboard boxes’. Typically mills are broadly separated according to “High Quality Papers” or “Kraft Mills”. Kraft mills make the same paper all the time, with small variations for basis weight or coatings. Quality Paper mills tend to make a variety of papers that mostly serve the printing industry. Newsprint falls someplace in the middle.  The Fourdrinier is the most common paper making machine. The above picture shows all of the major sections, but is simplified when compared to most machines in use today. Today’s machines are much larger (longer) to allow for faster line speeds. The Dryer Section may include over 100 steam cans (drums). Line speed is almost always above 500 feet per minute, and may exceed 1,000 feet per minute. Machines have also become wider. The average width exceeds 100 inches.

The Fourdrinier is the most common paper making machine. The above picture shows all of the major sections, but is simplified when compared to most machines in use today. Today’s machines are much larger (longer) to allow for faster line speeds. The Dryer Section may include over 100 steam cans (drums). Line speed is almost always above 500 feet per minute, and may exceed 1,000 feet per minute. Machines have also become wider. The average width exceeds 100 inches.  Head Box – receives the liquid pulp, with all ingredients ready to make the paper Flow Spreader – controls the pulp distribution on the Table Fourdrinier Table – a perforated conveyor belt that supports the pulp solids and allows the water to drain through Press Section – rollers that squeeze water from the pulp Dryer Section – typically steam drums (cans) that progressively dry the pulp as it turns to paper; the drying section may also include electric or gas infrared heaters and convection heating hoods. Calendar Stack – metal rollers that compress the paper to form uniform thickness; may be smooth or include some sort of pattern or texture. Reel – takes up the paper as it is finished

Head Box – receives the liquid pulp, with all ingredients ready to make the paper Flow Spreader – controls the pulp distribution on the Table Fourdrinier Table – a perforated conveyor belt that supports the pulp solids and allows the water to drain through Press Section – rollers that squeeze water from the pulp Dryer Section – typically steam drums (cans) that progressively dry the pulp as it turns to paper; the drying section may also include electric or gas infrared heaters and convection heating hoods. Calendar Stack – metal rollers that compress the paper to form uniform thickness; may be smooth or include some sort of pattern or texture. Reel – takes up the paper as it is finished

Converting

Paper is manufactured in very large rolls. In a separate process called “converting” the large rolls are sliced and cut into sizes used by the end-user. The converting process may also include additional calendaring to change the basis weight of the paper and give it various textures. Linen papers are typically calendared with a screen-like finish.

Tissue Machines

Tissue Machines are very similar to paper machines in over-all process, but they are much smaller in size and have a different kind of dryer section. Tissue is what is used to make toilet paper, paper towels, napkins, etc. Like paper, tissue is made from a pulp material, but is more often recycled and much lower quality materials. It is made in large rolls and later in a separate process “converted” to its final product.

Yankee Dryer

The Yankee Dryer uses a very large steam cylinder (18 – 25 ft diameter) surrounded by an air cap (hood). The hood supplies hot, high velocity air that impinges on the sheet. This way, drying is accomplished by a combination of conduction (the steam drum) and convection (moving air). The drying work is about evenly divided between the drum and hood.

Paper Coating

Many papers require a “coating” to be complete. The coating process may be connected to the paper machine where the machine is dedicated to making only one kind of paper, or may be a complete separate process in a totally different location. Common coatings include various clays to improve whiteness and absorption (such as premium ink jet papers) and silicone for water resistance and release for things like labels. The coating will make the paper wet or require curing. Dryers used on coaters are typically non-contact convection hoods and/or electric or gas infrared.

Paper Drying

After the pulping process, paper drying is the second most energy intensive process in the paper mill. Historically, paper was dried almost 100% with steam cans. Later, hoods were added. The most recent technology advancement has been infrared (IR). Initially the IR heaters were all electric, because of the concern with flammability and controllability of the gas units. New gas units have been specifically designed or adapted to the paper machine application, and now much of this market has gone to gas IR dryers. The IR units do not replace the steam cans (although in some cases, a couple steam cans may need to be removed to make room for the IR units) but are used to supplement steam drying. Sophisticated high speed controls read the moisture content across the paper sheet and adjust the IR burner temperature accordingly in a process called “profiling”. This has allowed production line speed to be increased. It is important that paper be dried to a specific moisture content. If it is too wet, it will cause later production and quality problems; if it is too dry, it may curl, become a fire hazard, break or rip, and cost more to produce. If a paper machine is “dryer limited” it means that the line speed cannot be increased beyond what the dryer section can dry. It is extremely expensive to add length to a paper machine to accommodate more steam cans. IR burners and other direct fired gas technologies can remove more water in a smaller space and therefore are often used to speed up production lines and/or increase paper drying quality. For More Information

Paper Drying

IR Paper Home | Industrial Home | ESC Home Page | Why Gas IR | Learn About Paper Drying | Activities and History | Vendors | About Us

© Copyright 2002-2015 Energy Solutions Center Inc.